Type and scope of certification

Two separate criteria are a basic requirement for certification:

1.) Participation and completion of the training or lecture with passing the exam in Six Sigma.

2.) Successful proof of the practical application of the Six Sigma method with two industry projects or the workshop.

Participation and completion of the Six-Sigma workshop

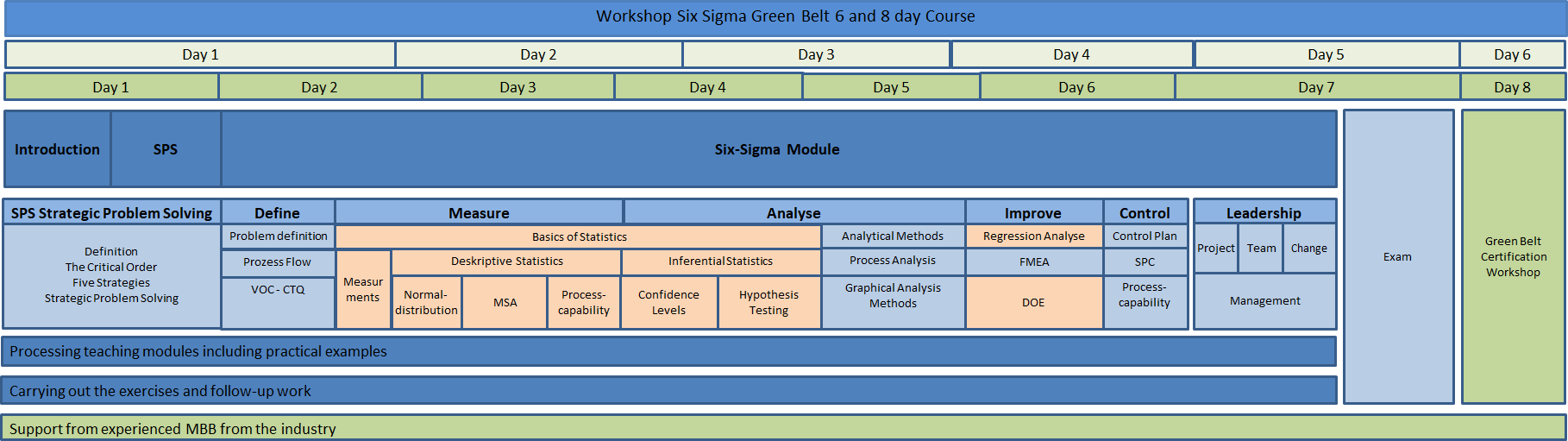

For the Six-Sigma Green Belt training, at least 7 teaching days with at least 52 teaching units lasting 45 minutes each must be completed in order to convey the content and achieve the required depth of teaching. The minimum requirements for the content of this Six-Sigma Green Belt lecture must be adhered to in accordance with the guidelines of DIN 13053-1:2011 and the quality and open source Six-Sigma guidelines. In the first step, the learning content of the lecture/training is certified by creating a lecture/training accompanied by practical application as homework. The second step is the successful participation in a Six Sigma exam; these two elements serve as entry requirements for the Green Belt certification.

Successful demonstration of practical and oral application of the Lean Six-Sigma methodology

Practical use:

The processing of projects that were carried out using the Six Sigma method with the participation and leadership of the Lean Green Belt is evaluated. The content of the project work for Green Belt certification is industrial projects that have a general improvement initiative, measurable VOC and a CTQ. The evaluation of the successful practical application of the Six Sigma methodology is carried out in two independent considerations. Firstly, the evaluation of the project work and secondly, the factually/technically correct application of the tools. The extent to which the project work was carried out successfully will be assessed by the Master Black Belt after the project has been completed.

Certification workshop:

We offer graduates of the Six Sigma lecture/training and the exam the opportunity to obtain certification in a 1-day workshop, followed by an integrated exam. During the certification workshop, you will be tasked with improving an existing process using the DMAIC methodology and selected tools through a simulation. Each participant will act as a project leader of a small project group during the workshop. After successfully participating in the certification workshop, you will be appointed a Lean Six Sigma Green Belt and receive the certificate.

The ability to use the tools correctly and the DMAIC and Lean process is assessed. Based on a problem specified by the examiner (Master Black Belt), the individual phases are run through and the project is simulated and specific questions about the problem are asked and evaluated.

Evaluation of the workshop:

- Are measurable results achieved through the improvement measures?Does the student/participant support the general improvement initiatives?Is the knowledge gained shared with others?Are the tools and the Six Sigma methodology integrated and applied into the daily workflow?Are other potential for improvement identified in addition to those assigned?

Requirement for completing the workshop

- The project achieves measurable results. The scope of the project is adhered to as documented in the project letter. The project was clearly carried out according to the DMAIC and Lean methodology. The project letter and presentation exist according to the templates. SIPOC or a process flow diagram is available. The customer voice (VOC) is available and CTQs / CTBs were derived. A cause - effect analysis was carried out and the inputs were prioritized. A data collection plan was developed which contains the essential CTQs / CTBs as well as the essential inputs. Where applicable, the process was improved through statistical and/or or graphical comparison between the reference performance of the process and the improved state. Where appropriate, a measurement system analysis was carried out (Gage R&R or auditor agreement). At least one of the listed statistical test methods was used: hypothesis testing, regression calculation, analysis of variance.